what are you looking for?

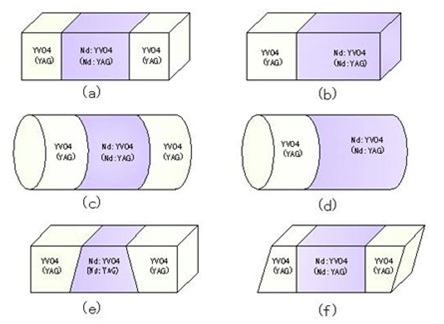

Diffusion bonded crystals consist of one laser crystal and one or two undoped material. They are combined by optical contact method and further bonded under high temperature. Diffusion Bonded Crystal helps to decrease thermal lens effect considerably of laser crystals, provides integral components to make compact lasers. HGO are able to supply various standard assembly and special customized bonding crystals.These diffusion bonded composite crystals have different wedge structures, Brewster angles, etc. It is used to effectively reduce the thermal effect of solid-state high-power lasers.

Shipping Port:

Fuzhou, ChinaLead Time:

5-6 weeksDescriptions

Diffusion Bonded Crystals largely reduce thermal lens effect of laser crystals, provides integral components to make compact lasers.

Diffusion bonding process:

1) Perfect optical contact between the crystals to be bonded;

2)Heating up of the two parts very slowly , to a very high temperature, probably 2/3 of the melt temperature or more, and exerting pressure to press the two parts together;

3) Keeping the bonded crystals for certain period of time at this high temperature, so that diffusion takes place;

4)Slowly cooling the crystals (24 hours) down to room temperature.

Product Serials:

1) YAG+Nd:YAG+ Cr4+:YAG; YAG+Nd:Ce:YAG+Cr4+:YAG; YAG+Yb:YAG+Cr4+:YAG

2)YVO4+ Nd:YVO4 + YVO4; GdVO4+ Nd:GdVO4 + GdVO4; YAG+Nd:YAG+ YAG

3) YLF+Nd:YLF+ YLF; YLF+Pr:YLF+ YLF

4) YAG+Ho:YAG+YAG; YAG+Tm:YAG+:YAG

5) Tisapphire+Tisapphire

Diffusion bonding for other crystal assambly types are also available.

Advantages:

1)To improve and enchance thermal the thermal performance;

2)Lower thermal lens effect of end surfaces.

3)Increase the output power of laser crystals

Main applications:

1)Industrial laser;

2)Biomedical laser/Medical laser;

3)Beauty laser;

4)Laser Lidar

5)Laser ranger finder

6)High power laser system etc.

Specifications:

|

Flatness |

λ/10 @ 632.8nm |

|

Wavefront distortion |

λ/10@ 632.8nm |

|

Surface Quality |

10/5 per MIL-O-13830A |

|

Parallelism |

10″ |

|

Perpendicularity |

5′ |

|

Bevel/Chamfer |

<0.1mm@45deg |

|

Chips |

<0.1mm |

|

Clear Aperture |

>95% |

|

Quality Warranty Period |

One year under proper use |

|

Coating |

AR/HR/PR (IAD, EB, IBS) |

|

Delivery Time |

5-6 weeks |

Why Choose HGO ?

HG OPTRONICS.,INC. is one of the earliest diffusion bonding crystals manufactures in China. Based on advanced bonding technology , wide experiences and techniques upgrading in the past over 13 years, HGO have become a top diffusion bonding crystals supplier. HGO has ability to provide different bonding configurations and various product structure for different laser systems and applications.

We are also interested in discussing and manufacturing new material combinations and structural geometries. Our goal is to provide high-quality composite materials that can provide solutions to your system needs, so we encourage all design submissions. Please contact us for more information and technical support.

Leave A Message

Leave A Message